Welcome to Arctech Fabricating, Inc.

Arctech Fabricating, Inc. is one of Southwest Ohio's premier certified welding facilities, offering certified TIG and MIG welding on virtually any materials group. Arctech offers in-house CNC Milling & Turning on low and high volume machined components. Certified to ISO 9001:2015 standards.

Arctech is a privately held company, founded in 1992 and incorporated in 1995. Our corporate leadership has an extensive history in aerospace industry management. From 1992 to today, our company focus has been to provide sheet metal parts, fabrications, and welding services to such industries as transportation, defense, food service, and energy.

Click a thumbnail below to learn more about each of our service offerings:

-

Military Systems and Components

Arctech is proud to support our military by supplying quality Military gun turret system components and ground support equipment. Arctech has supported our military for years making parts as small as tank door magnets to full size boat trailers and potable water systems. Our qualified team knows and understands the requirements involved with military work and can meet these requirements. We can even finish these parts with Military CARC coating. Though Arctech Specializing in these military products, we are not limited to just these components. Click on Contact & Location to call or email us and one of our sales engineers or manufacturing experts and let Arctech help you with all your military needs.

-

Aerospace

Arctech has been helping the aerospace industry for years by providing highly complex engine test stands and flight simulator frames and components. The aerospace industry has come to rely on Arctech expertise and skills in producing products that require complex weld fixtures and highly trained welders. They know Arctech can meet their needs and know that Arctech’s engineers will work closely with their engineers every step of the way if needed in the development process. Have an aerospace project that requires expert hands? Click on Contact & Location to call or email us and one of our sales engineers or manufacturing experts and let Arctech make your aerospace project a success.

-

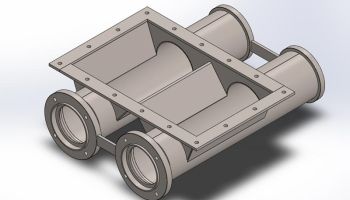

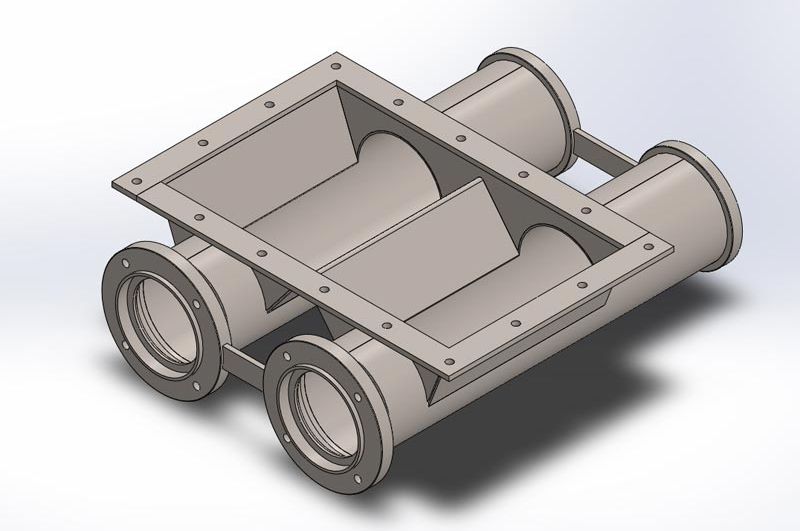

Industrial Pump Components

Arctech has a long history of supporting many big players in the industrial pump industry. We have made components for industrial pumps of all sizes. From components that could fit in your hand to pumps the size of a small room. Arctech is still providing high quality Industrial pump suction housings, pressure casings, feed hoppers, conveyor rods, stator adapters, and baseplates to this industry. We have in-house sanitary polishing and blasting making Arctech a one stop specialty industrial pump component shop. Need someone to make high quality pump parts for your company? Click on Contact & Location to call or email us and one of our sales engineers or manufacturing experts will help you today.

-

Inspection Equipment/Rotary Bases

Arctech produces many different high quality inspection equipment components and rotary bases for our customers. These components range in size from small to large and require the right equipment and skill to produce. Arctech has stepped up to the challenge by adding equipment and tooling to handle these products. We are dedicated to our customers and our processes and will always do what it takes to get a great product every time. So, if you have any inspection equipment, rotary base, or other similar needs, let the professionals at Arctech handle our next project. Click on Contact & Location to call or email us and one of our sales engineers or manufacturing experts will be glad to help.

-

Turbine and Turbo Components

Arctech has been involved producing many complex parts and weldments for all different industries. One of our favorites has been producing hydro turbines and turbo components. These products require a high level of skill and discipline to achieve a high-quality product. Our engineering and manufacturing experts create a step-by-step process that is followed by our production specialist and checked quality team every step of the way. If you have a turbine or turbo project, Arctech would love to make your simple to complex parts and sharpened our skill sets to the next level. Click on Contact & Location to call or email us and one of our sales engineers or manufacturing experts would love to discuss your needs.

Your Experts in Fabrication. Top Quality Standards.

Click a thumbnail below to learn more about each of our service offerings:

-

Assembly and Kitting Solutions

From small bolt together assemblies to large engine containers, Arctech has the team and skills to assemble your products. Need your parts kitted? Arctech has you covered as well from bagged and boxed to vacuum packed kits.

-

CNC Machining

Our machine shop is ready to meet your machined parts needs with our wide range of multiple axis mill and lathe machining plus CAM capabilities. From small to large and low to high volume parts, we have the ability, skill, and experience to turn your drawing or CAD file into a final product.

-

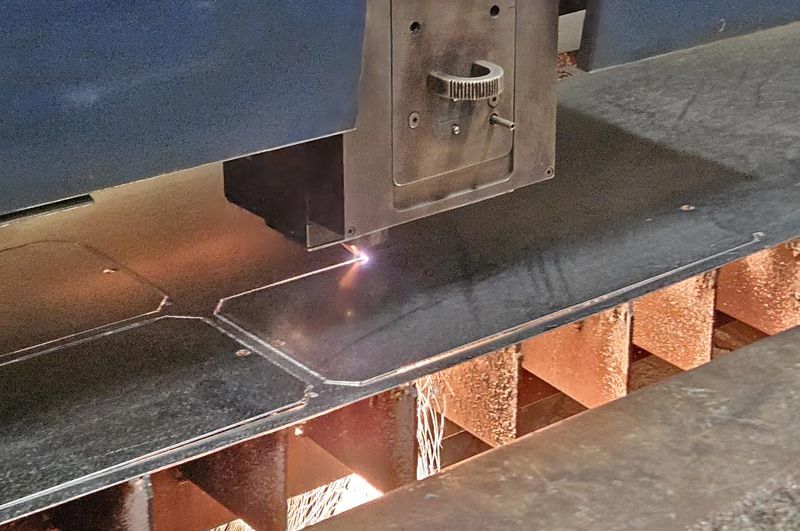

Laser Cutting and Forming

Arctech is ready to meet your metal fabrication needs with our laser, saw, and shear cutting capabilities plus our brake press forming and sheet metal rolling capabilities. Our experienced team has the knowledge and skills to make your metal fabrication projects a success.

-

Manual and Robotic Welding

From small to trailer plus size weldments, Arctech is there to meet your needs with superior quality and certified welding. We are weld certified to AMSE Section VIII & IX and AWS D1.1, D1.2, D1.3, D1.6, D1.9, & D17.1 specifications. Our highly trained, experienced, and skilled welders are ready to meet all your welding needs.

-

Manufacturing Expertise

With decades of experience, our knowledgeable engineering and manufacturing team can offer suggestions to make your part manufacturable. We can even help by offering suggestions to reduce manufacturing cost. Whether you have existing parts or Prototypes, let Arctech help you save and succeed.

-

Powdercoat & Finishing

Need a finish to your part? Arctech offers a complete solution for your needs. We directly offer powder, liquid spray, E-Coat, and Military CARC coating and partner with vendors to offer anodize, oxide, passivation, plating services, and more. Need a specific surface finish? Arctech offers blasting (glass, grit, and sand) and polishing services including sanitary polish.

-

Prototyping Services

Need to turn your CAD files into something tangible? Our experienced team has helped many companies develop and produce top quality prototypes. Let us help you with your prototyping needs.

What's Next?

As Arctech continues to grow, we are adding further capabilities and implementing process improvements to our in-house processing. Arctech has recently implemented the EOS system to make sure we continue to improve and add value to our customers and ourselves.

Arctech recently purchased a new fiber laser to meet and exceed our customers’ demands. Visit each of our 'Services' pages below to see everything Arctech can do for you and your business.

Timeline

-

YearMilestone

-

1992Founded

-

1995Incorporated

-

2005Guiness World Record

-

2010Improved World Record

-

202410,000th Customer

Our Guinness World Record - Twice

In October 2005, Arctech Fabricating was part of a Guinness world record setting event, making a 12 foot diameter, 2020 lb, edible pumpkin pie in New Bremen, Ohio.

In September of 2010 we a part of breaking our 2005 Guinness world record with a 20 foot diameter, 3699 lb, edible pumpkin pie. In both cases we made the pan for the Guinness record setting events.